Man, getting this engine just to start has been killing me these last few months. I went from a 8-1 crank wheel "M-N Crank Wheel w/ No Cam Synch" to a 8-2 which seemed better at finding the missing tooth at the time. Put the harness on the JimStim and it runs fine with a 12-1 trigger except at higher rpm >3000rpm the signal started to cut out on the scope?!? I ignored that for now bc I just want to get the engine running first. I then switched the 8-2 for a 16-1 wheel, which actually started the engine finally but was almost impossible to gain synch during cranking (I just got lucky once or twice out of 40 tries with a 100% cranking pulse tolerance)..

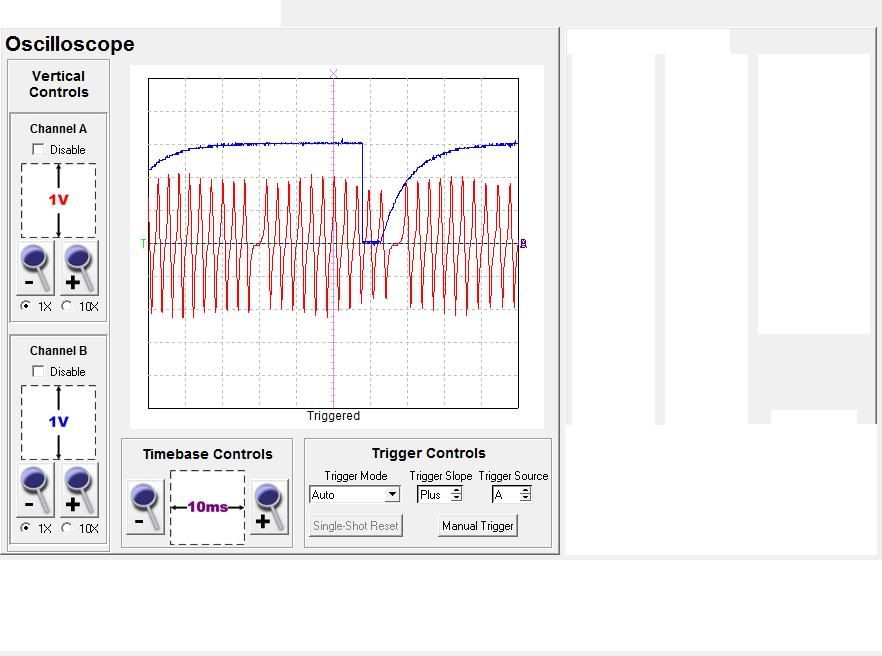

I then tried going "Normal Crank Trigger w/ Cam Synch" with a 2 tooth wheel (formerly the 8-2), using one tooth for each ign event. I wired the existing Cam Hall Effect sensor, supplying 5V, wiring the output into VRIN2+ (4) and grounded to shield (31)of VR crank sensor. Cam Pulses look fine to me on the scope: (A lot better than the crank sensor).. Any ideas for the crank sensor signal conditioning please???

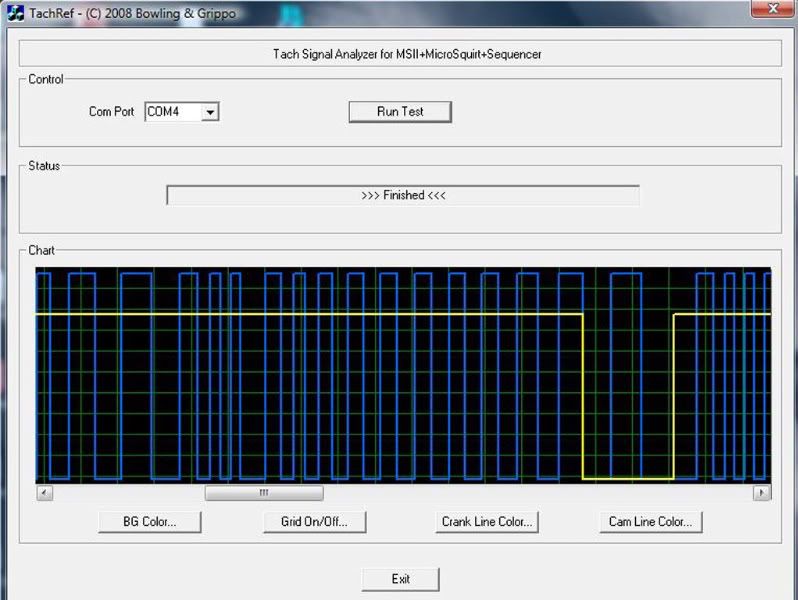

I then downloaded the tooth analyzer and flashed the appropriate software into my us. Is it normal for the tooth analyzer to take extra time after cranking to process the plots. It ends up being very zoomed in, but you can't zoom out?

The crank VR sensor is false triggering a whole bunch of times, any ideas? It looks like its picking up the noise seen on the scope trace above.