1) High power grounds - these are the returns for the fuel injector and ignition drivers, and the fuel pump/fast idle/spare output drivers. There are three wires on the connectors for these, going to pins 21, 22, and 23 on the AMPSEAL - these are for the high power ground path. All three (3) of these wires need to ground direct to the engine block. It is important to run all three wires because it will reduce both the resistance and the overall inductance of the ground return path. Each wire has a resistance, and using three of them in parallel reduces the overall resistance. Equally important, each wire has an inductance, and inductances do not "like" fast-changing signals (like a pulse from a spark) and can cause very brief voltage offsets in the ground path. By having multiple wires it is the same as having multiple inductors in parallel, resulting in an overall lower inductance.

At the point on the engine block where the grounds hook together, it is a good idea to run a separate wire from this junction back to the battery as well. This is redundant, however it often cleans up noise from sources like the starter motor. And, if it does help then you should take another look at your big positive and negative wire on the battery...

Since we are talking battery - the point where you pick up the +12V to power the MicroSquirt is very important. This will go thru a relay in order to turn on and off the MicroSquirt, and the power source for the +12V on the relay needs to go back to the battery, or a path that leads direct to the battery without a long run of wiring. Just like for the grounds, I recommend running a separate wire from the relay direct back to the battery just to be sure.

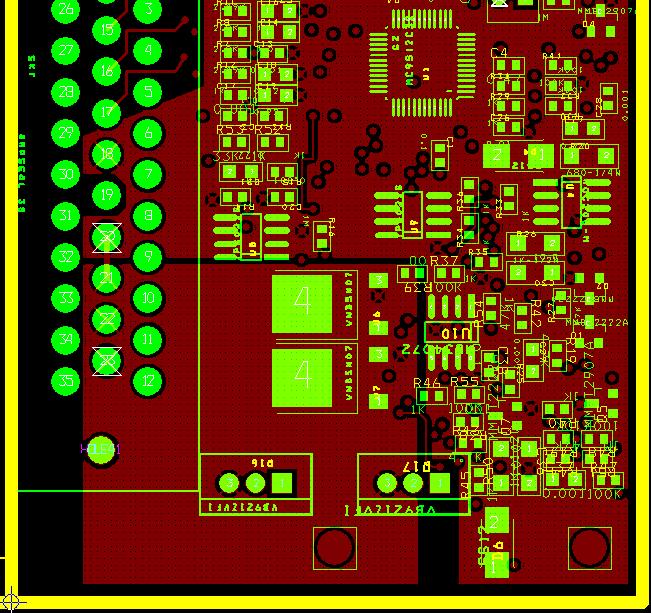

To illustrate the grounding on the MicroSquirt, here is a picture of the ground plane layer of the board:

The red square on the lower left is the ground plane for the high current drivers. Note how this is separate from the other red ground plane above and to the right, which is the low current plane.

2) Sensor ground - the coolant sensor, intake air temperature sensor, throttle position sensor, and external MAP sensor needs to be grounded back to pin 18 on the AMPSEAL. This is the low-current sensor return path and it needs to be kept away from the high power ground. This wire hooks directly to the sensors only and not to the engine block - it is its own return path.

3) VR return ground - there is a separate VR(-) input on the AMPSEAL, this needs to be connected to the VR sensor(s). If you are using two VR sensors, return both back to this wire (these are low current and can be shared on the one wire retrun path) Do not ground the VR sensor anywhere else, return the ground back to the VR(-) terminal. On the MicroSquirt, this return goes directly back to the VR input circuit's transistor/op amp and not to the ground plane, this keeps the high amplitude VR voltages (and resulting currents) isolated to the VR circuit.

4) Serial return - the serial cable on the MicroSquirt has a separate ground return path thru the AMPSEAL connector. This return goes direct to the RS-232 transceiver (and not thru the ground plane, keeping the noise off...).

With the small size of MicroSquirt, keeping the grounds straight is important. It is not hard, just keep things in logical groups - high power stuff goes to engine block, sensors on their own ground loop, and the VR sensor is also separate.

To help visualize the ground paths for the high power drivers and the sensors, I have generated a "Mickey Mouse(R)" drawing of the current paths:

The bottom of the image is the high power path, showing one ignition coil as an example. The current path is from the battery to the ignition coil to the MicroSquirt driver and back - see the light blue arrow path marking. The same goes on for the injector and general purpose outputs. Lots of juice flowing on this path, it needs to stay away from the sensors. It also needs a low resistance/inductance loop - you can see that the battery plays an important part of the path...

Speaking of the sensors, on the top of the image is the sensor return path. The Vref is the reference voltage generated by MicroSquirt, it passes thru the sensors and the return ground path comes back to the MicroSquirt. Only one return path is required for the sensors because it is comparatively low current, and we all know that voltage drop across a wire is driven by Ohm's law...

Finally, it is wise to dress the wires such that the high current "stuff" stays away from the sensor/VR/serial wires. Remember that an ignition coil flyback pulse is 350 volts with a current of 7 amps or so, a nice ElectroMagnetic Pulse (EMP) generator! If this gets into the sensors, VR, or serial connections then you will get all sorts of weird stuff going on...

- Bruce